Small fleet, big data

The Western Gulf of Alaska (WGOA) fleet is a relatively small group of local fishermen that are forward-thinking and open to change. They are collectively organized as the Peninsula Fishermen’s Coalition, and live primarily in the communities of King Cove, Sand Point and False Pass within the Aleutians East Borough. These are coastal communities without road systems; the cost of traveling to them is at least a thousand dollars, a two-hour flight, and a few years off your life during the turbulent final descent.

WGOA fishermen have diverse portfolios that allow them to fish year-round, rotating between fisheries. Vessels are typically small (less than 60ft in length) and are designed to be versatile, capable of switching between trawl and fixed-gear for groundfish, and seine gear for summer salmon. Fishing not only supports local fishermen, but entire communities, with a significant portion of City and Borough revenue generated from landings taxes – funds that ultimately go back into community services such as schools and infrastructure. All this to say, fishing is the lifeblood of this region. So, when an issue arises that has the potential to completely shut down a fishery, folks pick themselves up by their Grundens straps and figure it out.

Data modernization in the WGOA fleet started small enough, with fishermen simply trying to solve an age-old issue that had been plaguing them for years: salmon bycatch. Concern over salmon bycatch is not particularly unique to the WGOA, but the method by which salmon bycatch is accounted for is unique in the WGOA, and has been a point of contention for years. Ultimately, it was the fishermen who decided to take action and find a way forward.

One fish, two fish

The issue of salmon bycatch is sensitive throughout Alaska; not only are salmon of high economic value, they are iconic and even sacred to some. It makes sense that regulators and managers have gone to great lengths to keep salmon bycatch at manageable levels, and reduce bycatch as much as possible.

Every year, stock assessment authors and managers publish Total Allowable Catch (TAC) limits for pollock, alongside hard cap limits of Prohibited Species Catch (PSC) for Chinook salmon bycatch. When the salmon hard cap is met, the pollock fishery is closed and fishermen forgo harvesting any remaining pollock quota. Ergo, the accurate and timely enumeration of salmon caught is critical.

In the Gulf of Alaska (GOA), vessels participate in the Partial Coverage observer program. Less than 30% of trips are monitored by a vessel observer, who then follows the offloaded catch into the plant to conduct salmon census. The count of salmon is then extrapolated to the entire fleet, thus producing a rate and total number of salmon caught against the cap. This method works well-enough when a vessel delivers directly to a shoreside processor. But in the WGOA, the pollock fishery spans a massive geographic footprint, with fishing grounds located over a day’s worth of travel from port. In a non-rationalized fishery (i.e., derby-style instead of allocated) like GOA pollock, there isn’t enough time to steam back and forth to the plant to offload, not to mention it’s generally inefficient and uneconomical. Instead, processors deploy tender vessels that retrieve catch from catcher vessels (CV) and transport it back to the shoreside plant. This model has proven to be highly successful, allowing fish to retain value by processing it as quickly as possible, and allowing CVs to remain at the grounds to continue fishing.

Here is where things get sticky: tender vessels cannot carry observers. In 2013, the observer program was restructured to remove potential biases that could negatively impact the statistical reliability of catch data. Unfortunately, the niche use of tenders was not considered, and the restructuring did not fully incorporate the needs of the tender component. Under the current regulated program, when a CV that is delivering to a tender is selected for observer coverage, the observer must complete all of their tasks from the CV and cannot follow the catch into the plant to enumerate salmon (like they would if they were observing a CV delivering directly to a shoreside plant).

Unfortunately, it is impractical for an onboard observer to accurately sort and count salmon, and complete all of their other duties, before the catch goes into the hold. So in lieu of a true salmon census, NMFS estimates Chinook salmon PSC by using “at-sea” samples collected by vessel observers, meant to be representative of the entire haul. The count of PSC salmon is then extrapolated to the delivery, and ultimately the entire fleet.

No one said it better than John Shepherd: “Counting fish is like counting trees, except they are invisible and keep moving.” So, it’s not hard to understand why representative sampling and extrapolation are used in fisheries assessment – it’s often unavoidable. The issue is that abundance of a given species and sample size affect the level of precision, so estimates for a relatively rare species such as Chinook salmon are biased and imprecise – and yet, are still used to manage the fishery. An at-sea sample with a few concentrated salmon may extrapolate to hundreds of salmon, regardless if hundreds of salmon were actually caught. Combined with small salmon caps, the WGOA fishermen are running two races: a race for fish and a race against salmon bycatch.

Necessity is the mother of…modernization

Meanwhile, in the North Pacific fisheries world there was a concept that was quickly gaining ground: electronic monitoring (EM). The WGOA fishermen quickly recognized EM technology as a possible solution for better salmon data. The WGOA fleet, alongside the Central Gulf of  Alaska and Bering Sea fleets, began designing a pilot EM program that would work for their fisheries. The pollock fishery would operate as maximized-retention (i.e., retaining as much catch as possible); volunteer vessels would be monitored for compliance with EM for 100% of trips in lieu of vessel observers monitoring less than 30% of trips; and observers would be placed into the shoreside processing plants to accomplish hands-on sampling duties (including salmon census).

Alaska and Bering Sea fleets, began designing a pilot EM program that would work for their fisheries. The pollock fishery would operate as maximized-retention (i.e., retaining as much catch as possible); volunteer vessels would be monitored for compliance with EM for 100% of trips in lieu of vessel observers monitoring less than 30% of trips; and observers would be placed into the shoreside processing plants to accomplish hands-on sampling duties (including salmon census).

With a program designed and funding support from the National Fish and Wildlife Foundation’s Electronic Monitoring and Reporting Grant Program, the WGOA fleet set sail towards EM. The project started in 2019 as a pilot, and moved into at-scale implementation under an NMFS Exempted Fishing Permit (EFP) in 2020. The project will continue to operate and improve under the EFP, until regulatory implementation slated for 2024. The WGOA benefits in all the well-known ways such as removing the burden and safety-hazards of vessel observers, reducing the cost of monitoring, etc. Arguably more important though, the WGOA finally has an opportunity to improve data collection and implement salmon census for tendered deliveries. Unbeknownst prior to implementation of this project, using EM as a solution to one problem would reveal an entire ecosystem of data modernization ripe for discovery.

Ripping Off the Band-Aid: Logbooks and eLogs

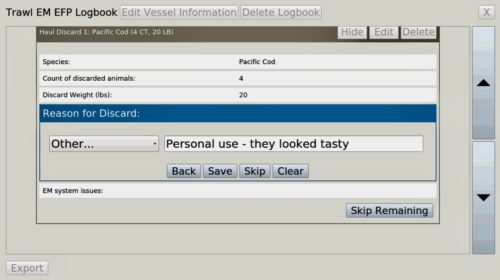

One initial concern was how to maintain a verifiable chain of custody; i.e. how to monitor catch through the entire process. Swapping vessel observers with EM meant fishermen would need to supplement EM video and landings data with self-reported logbook data. Logbooks are a tool commonly used in North Pacific fisheries management but had not been implemented in the <60ft vessel groundfish fleets until the EFP.

We started the program in 2019, by developing paper logbooks. Tender logbooks are relatively simple, as they only document the transfer of catch rather than the catch itself, but they were a completely new and untested concept. Logbooks on CVs proved more of a challenge, however, as they provide a detailed report on their catch, not to mention managing triplicate copies that needed to be distributed to various destinations (and with any manual data entry, there is an added opportunity for human error). The process seemed messy, begging the question, “would this realistically work under a regulated program?”

Outcome: In collaboration with the fleet, Saltwater Inc. and Chordata developed an electronic logbook called eLog, that is tied directly to the EM system. The eLog was designed to autofill elements that were known to the EM system, such as gear type, vessel identifier, approximate haul positions and times. The skipper, as necessary, could override all of these elements, but the idea is to simplify data entry for skippers and reduce errors. The eLog entries are validated as they are made against a set of rules designed to catch common data entry issues. Data entry will also improve for processors; when they receive the eLog they will no longer have to decipher handwriting when inputting logbook data into eLandings. Since paper logbooks were a new element anyway, there would need to be extensive training and outreach no matter what. It just made sense to rip the band-aid off, and design a logbook process that would actually work for the fleet under a regulated program, even if it took a bit more upfront capital and effort.

At first, eLog was piloted side-by-side with paper logbooks, with the intent of comparing the data collected and building in redundancy (just in case). As it turns out, trying to record and manage two logbooks was confusing and impractical for the fleet. For the fall season of 2021, the vessels will only be required to use eLog, but will have backup paper logbooks if necessary.

Finding Creative Ways to Make It Work: Tender Mobile EM Systems

Developing an EM program that includes tenders is complicated and requires an intimate knowledge of how the fleet operates. The greatest advantage of working under an EFP is having the flexibility to learn from experience and adapt the program as needed. When the EFP was  being developed, the EFP team established a set of “rules” that tender vessels would need to adhere to, in order to ensure that the chain of custody for catch was maintained. Essentially, (1) all EFP catch must be retained and delivered to an EFP processor; (2) tenders cannot mix catch between EFP and non-EFP during the same trip; (3) tenders cannot mix catch between NMFS statistical areas during the same trip; and (4) tenders must deliver all catch to one EFP plant, no partial offloads.

being developed, the EFP team established a set of “rules” that tender vessels would need to adhere to, in order to ensure that the chain of custody for catch was maintained. Essentially, (1) all EFP catch must be retained and delivered to an EFP processor; (2) tenders cannot mix catch between EFP and non-EFP during the same trip; (3) tenders cannot mix catch between NMFS statistical areas during the same trip; and (4) tenders must deliver all catch to one EFP plant, no partial offloads.

These rules seemed easy enough on paper, until the season started and the nuance and unpredictability of the tender fleet was revealed. The ultimate goal was to develop an EM program that would maintain the operational efficiency of using tenders, but the issue was an onion, each layer giving way to a new challenge. The most obvious issue was not having enough tenders equipped with EM; if fishing is hot, a processor may rapidly deploy more tenders than initially anticipated. But adding a tender to an EM program has many considerations: Vessel Monitoring Plans (VMPs) need to be developed and approved; installing a traditional EM system requires a technician to travel to port; processors may not contract the same tenders or even know which tenders they’ll be contracting until right before the season. Installing a traditional EM system is not only logistically challenging, but it simply doesn’t make sense.

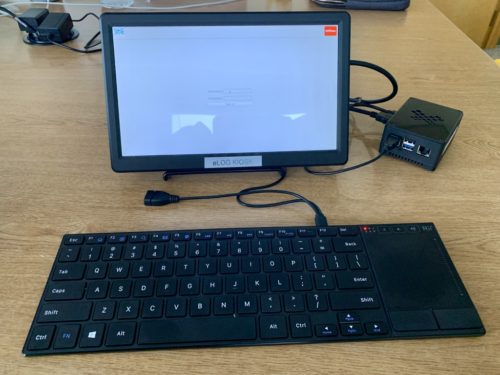

Outcome: Thus, the Mobile System (MBS) was born. Because tenders are simply transporting fish, they require fewer cameras and configurations are less complex than a CV.

Saltwater Inc. was able to develop a completely portable EM system that fits within a small pelican case, and can be installed by a skipper or crew member with over-the-phone guidance from a technician. These can be easily installed and uninstalled for non-permanent tenders, and housed at the plant. By providing plants with extra MBS, they have the flexibility they need to make last-minute operational decisions without compromising their participation in the EFP (or a future regulated program).

At the end of the day, the program as designed and the EM systems as built have to work for everyone participating, in a way that doesn’t severely disrupt operational efficiency.

Shifting the Paradigm: A Fishermen’s Data Portal

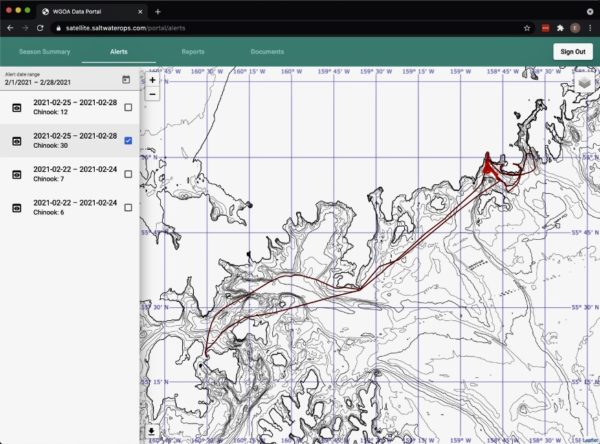

By 2021, the EM EFP was well on its way to addressing the fundamental questions of “how do we improve the actual data” and “can EM be used to accomplish the EFP objectives.” It was time to start shifting the question to, “now that we have better data, how can we best use these data?” Salmon accounting did improve by moving observers into plants to allow for salmon census of observed trips. What was missing was an easier and faster way to get the landings data back into fishermen’s hands, specifically, data on when, where, and how many salmon were being caught.

No one wants to incidentally catch salmon, and any fishermen you talk to will tell you the same. But in a race for fish, time is of the essence. Once a vessel offloads, it goes right back out to fishing and doesn’t have time to wait for a finalized fish ticket. In some seasons the fleet may have as little as a few days to execute a fishery.

In order to make in-season operational decisions, the fleet needed a way to get salmon PSC information in real-time. While this is a highly specific and localized issue, a larger and more universal need hangs like a dark cloud over fisheries management: data ownership, access and use. The current infrastructure for data systems has developed in a way that revolves around fisheries management, and for many years this worked. Fishery managers asked the questions, outlined which data were necessary to answer their questions, and industry complied by providing data. But at some point, likely due to the legal and political concerns surrounding confidentiality, a wall started to grow around these data systems, inadvertently excluding fishermen and making access to their own data difficult.

Fisheries-dependent data has proven to be valuable and versatile in application, finding its way into the hands of stock assessment authors, researchers, economists and the like. So why shouldn’t fishermen be able to access and use their own data too? The WGOA fishermen’s desire to improve salmon PSC monitoring may have been the original catalyst, but it had now become the perfect vehicle to test a high-level concept: a fishermen-centric data portal. Fishermen wanted to design a platform to easily view and access their own data, giving them the power to use those data for other purposes; for example, improving business operations or avoiding salmon bycatch. The pieces were all there, the puzzle just needed to be solved.

Through the EFP, vessels already had the EM infrastructure; data reviewers were already receiving three data streams (EM video, eLandings, logbooks); and with the new eLog implementation, logbooks could be readily uploaded via USB drives at the plant. With funding support from Net Gains Alliance and through collaboration with the fleet, these resources were leveraged to create a proof-of-concept data portal where fishermen can directly access their own data. They are able to get timely access to fish tickets, view their own confidential data through an individual login, as well as drive reports from trawl EM-reviewed trips.

Outcome: The portal infrastructure has now been developed, and full-scale trials are underway to test its analytical capability, namely tracking salmon bycatch.

With cooperation from the processors, direct access to eLandings is providing near real-time fish ticket data. Processors have also agreed to facilitate the upload of eLog drives by installing small, easy-to-use kiosks. From these data, salmon bycatch count and geospatial data is being aggregated to the fleet-level and displayed on the home page of the data portal as 1) salmon hotspot map; 2) salmon PSC count against hard cap; and 3) PSC catch rate (displayed against catch rate of target species i.e. pollock quota).

With input from PFC, PSC warning triggers were programmed to automatically notify fishermen when PSC catch reaches the specified threshold. In this instance, a bottom-up approach allows the fleet to address not only a present-day issue, but also create a platform with the capability to serve as a data repository and use fishery-dependent data (and possibly other types in the future) to generate analytical products. This has also been a valuable lesson in leveraging available resources; killing as many birds with as few stones as possible, so to speak. A lesson that would carry forward almost immediately….

Leveraging Resources: EM Systems Across Fisheries

A common method of comparing costs between an EM system and a traditional form of monitoring (in this case, at-sea observers), is to look at the per-sea-day cost. While there are many complex methods of calculating the cost of EM, simple math would suggest that the cost of an EM system is inversely proportional to the number of sea-days the EM system is used.

Fortunately, the term fisherman is often synonymous with businessman. Immediately after NMFS published the final rule to allow EM on fixed-gear vessels, WGOA fishermen started calling and asking how to use their EM systems when they fish fixed-gear. Genius! The vessels already have EM systems, why not use them across multiple fisheries? Alas, if it sounds too easy…it probably is. The fixed-gear EM program was tested and designed for non-trawl vessels, therefore the final rule only allowed participation from non-trawl vessels. Ipso facto, the characteristic of switching between trawl and fixed gear now kept them off the guest list to the EM party.

The solution seemed obvious. Just allow trawl vessels into the EM fixed-gear selection pool, right? Surprise, it’s another onion! Yes, reprogramming the selection pool needed to happen, but there were many layers to consider. What are the different requirements for EM configurations between trawl and fixed-gear vessels? Will cameras need to be moved and if so, can the skipper do that? How should a vessel monitoring plan be written to accommodate multiple EM fisheries with disparate data objectives?

What’s more, the catch handling protocols in the regulated fixed-gear program are challenging for participating pot vessels to adhere to. Protocols require the catch from each pot to be completely cleared from the sorting table prior to the next pot being offloaded (to allow data reviewers to discern between hauls), and the crew must sort all the catch in the camera view (for species composition and enumeration) before the table can be cleared. This task is difficult and frustrating at best, and at worst, impossible or even dangerous. It simply doesn’t make sense to add more pot vessels to the regulated EM pool, until protocols in place are practical in application and support vessels are staying in compliance.

Outcome: This is a perfect opportunity for some mutual back scratching. WGOA trawl/fixed-gear vessels want to demonstrate trawl EM systems could be used in the fixed-gear EM program, and NMFS now has a pilot-size set of volunteer vessels willing to pilot alternative catch handling protocols for pot vessels. In collaboration with NMFS Fisheries Monitoring and Analysis (FMA) division, a proposal was developed to work with 3-5 trawl EM vessels to investigate EM configurations and VMPs suitable for trawl/fixed-gear vessels. Vessels will simultaneously run EM and carry onboard observers, to allow for side-by-side comparison and to ground-truth alternative catch handling methods (primarily for pot cod and sablefish fisheries).

This project is still in a preliminary phase and is awaiting confirmation of funding, but assuming everything goes as planned (because that always happens, right?), the WGOA vessels will be eligible to participate in the regulated fixed-gear EM pool using their trawl EM systems by 2023, and catch handling protocols will improve for all pot vessels that participate in the program.

Coming Full Circle: EM in the Plants

Looking forward, there is still one box left unchecked. Not a particularly new concept, but one that is looking extra shiny and appealing after balancing the books from year one of the EFP. As noted previously, under the EFP, observers that were once stationed on vessels were moved into the shoreside plants to complete their sampling duties. One of their core responsibilities is to ensure that any salmon in an offload is properly sorted and accounted for, so they ensure an accurate census and collect genetic samples.

This involves taking a highly skilled (and commensurately paid) biologist, asking them to only stare at a sorting belt for hours, and not complete any of their other tasks until the offload is complete. Over the course of a year, that’s an inordinate amount of labor (and cost) wasted on human-security cameras, when that time could be concentrated on actual data collection priorities. Not to mention, the burden of housing, feeding and facilitating observers is squarely on the processors. That sounds like a job for…super EM!

Outcome: That’s right, it wasn’t a far leap to go from human-security to cameras to actual security cameras. Especially since there is precedent for similar use in the Bering Sea American Fisheries Act (AFA) fisheries. In collaboration with agency staff and processors, a proposal was developed to test EM in the plants. This project would include looking at the layout for each plant, exploring what configurations are necessary to monitor the entire sorting process, having a secure location for salmon to be stored, and establishing a method for any after-scale salmon (i.e. salmon that are missed during sorting) to be accounted for. Observers could then review video for each offload to verify all salmon were accounted for. To take it one step further (because, why not?), the project will develop and test a “salmon chute” system that incorporates EM cameras, controlled lighting and data storage to capture images of individual fish as they are conveyed through the chute. Images from the chute would capture data on salmon species, counts, and lengths. The ultimate goal is to use data from the images to develp an algorithm that will automate this process (e.g. length, count, speciation), freeing up even more observer time to focus on biological sampling.

Final thoughts

Within the span of a few years, EM has become ubiquitous in the WGOA. It is the hydra of technology, you cut one project off your list and another one grows in its place. But less menacing, and infinitely more useful. Even with many growing pains (especially for the less-technologically-inclined demographic), the fleet is pleased with the cost-savings and relief of having one less body to shuffle around and keep safe. Some valuable (and possibly transferable) lessons include:

-

- Empower fishermen: Management of fishery-dependent data has evolved into a one-way street. The basic data flow goes something like: fishermen create data, data are transferred to governing agencies, data serves as input for varying functions, the output is some unrecognizable product of integrated data (e.g. stock assessment models). This process leaves little room for fishermen to control, access and capitalize their own data. Yet they are the ones on the ground, who intimately understand what’s working, what isn’t and how to fix it. Give fishermen ownership over their own data, and what follows is an increased sense of accountability and possibly even incentive, to use their data to address their issues or make improvements in their fishery.

-

- Kill as many birds with as few stones as possible: Assess the needs and/or problems to be solved (short and long term), take stock of available assets, then identify if you have resources that can be leveraged. Assets may be tangible like an EM system, or they might be intangible like data or subject-matter expertise. These are resources that can be used to build on existing work, or to efficiently (in term of cost and time) branch out into other projects without starting from scratch. For example, pursuing a data portal was a no-brainer – the problem and objectives were clear, and the EM/eLog/data streams were already available through a previous project.

-

- It has to work for everyone, or it will work for no one: These projects could not have been imagined (let alone executed) without participation from every facet of the fishing universe; fishermen, tenders, processors, EM providers, data reviewers, software developers, management staff and scientists, NPFMC and staff, all with varying needs and expectations. For a program to hack it in the real (regulated) world, it’s just as important to design EM systems and protocols in a way that is achievable for vessels, as it is to collect the right kind and amount of data for stock assessment authors, and as it is to work within given political directives.

-

- Problems are like onions: They have many layers and they’ll probably make your eyes water. Keep peeling; eventually the layers will run out and all that’s left is a solution!